Located within the Electro-Optics and Electronics (EOE) Division of ARL, we have extensive R&D, prototyping, testing, and manufacturing capabilities for electronic, piezoelectric, and optical materials and devices.

Our lab focuses on applied research and technology transition with a long history of working with the DoD and industry to solve critical problems and develop next-generation electronic materials and devices. The Electronic Materials and Devices Laboratory has facilities in State College and Freeport, PA which include >60 bulk and thin film growth systems, full crystal & ceramic fabrication facility, 3D printing center, and a semiconductor packaging lab.

Our staff also leverages the state-of-the-art Materials Characterization and Nanofabrication laboratories on Penn State’s University Park campus which enables us to truly support every step from bulk material growth/synthesis to final packaging and testing of devices.

- Material growth and synthesis – >60 bulk and thin film growth systems, including SiC, GaN, diamond, oxides, nitrides, hBN, cBN, 2D materials, piezoelectrics, and dielectrics

- Fabrication and polishing – Full CNC fabrication and polishing capabilities to process bulk crystals into epi-ready substrates and ceramics into final parts

- Advanced ceramic processing – Full prototyping capabilities, including powder processing, spray drying, tape casting, lamination stacking, pressing, sintering, and machining

- Materials characterization – Access to >50 characterization tools, including XRD, OM, SEM, AFM, WLI, Raman, ellipsometry, FTIR, and PL

- Electrical characterization – Extensive electrical characterization setup, including probe stations, low-temperature Hall/van der Pauw, Lehighton, and four point probe tools

- Device design and fabrication – Full design and fabrication capabilities in a Class 1,000/100 cleanroom, including e-beam/stepper lithography, dry etch, wet etch, evaporation, sputtering, and atomic layer deposition

- Electronics wire bonding and packaging – Dedicated lab for eutectic die, ball, and wedge bonding of electronic devices

- 3D printed electronics – Direct ink writing and inkjet printing of conductive, ceramic, and functional materials featuring an nScrypt multi-material “Factory in a Box” and Hyrel Hydra and Viscotec printers

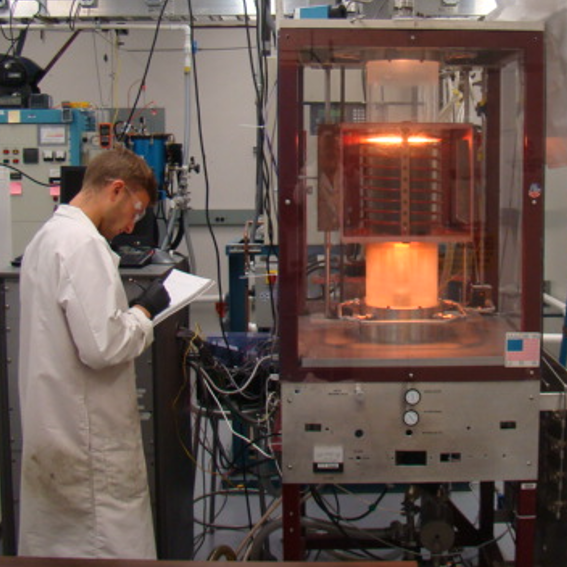

Sintering components at >2000°C

in a cold wall vertical induction furnace

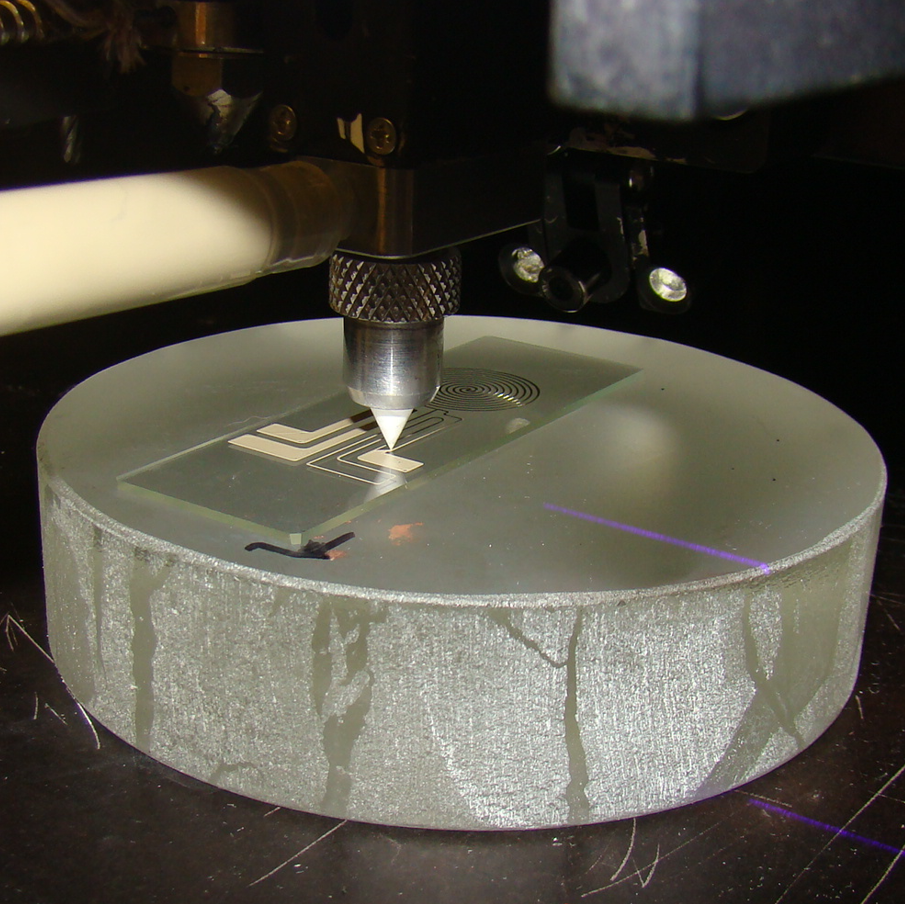

3D printing a sensor by direct ink writing (DIW)

using an nScrypt system

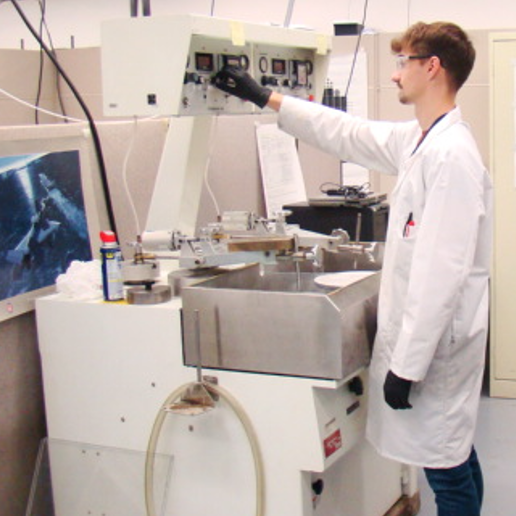

Chemi-mechanical polishing substrates

on a Strasbaugh